Warehouse Management

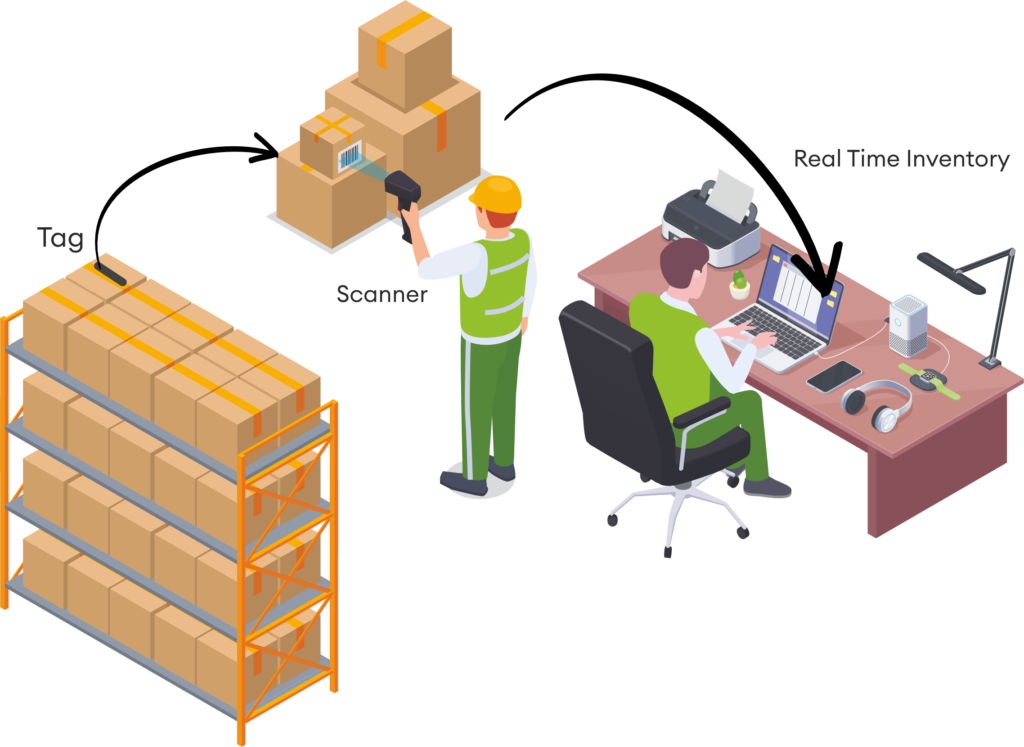

The implementation of RFID technology has improved operational efficiency and productivity in distribution centres and warehouses around the world. RFID technology typically complements data capture technology (like barcodes) already used in warehouse and distribution centres.

Benefits Of RFID In Warehouse And Distribution

- Reduces labour costs: Decrease primary warehouse worker functions including everything from inventory to pick/pack/ship and put away.

- Increases inventory accuracy: Improve receiving efficiency and accuracy as well as picking and ordering accuracy.

- Reduces inventory stock levels: Improve stock and demand generation visibility.

- Reduces unsaleable and out-of-stock items: Leaner and lower levels of inventory mean faster inventory turns and less stagnant stock.

- Improves customer satisfaction: Ensure the right goods reach the right customer at the right time.

RFID In Receiving

In receiving items, cases and/or pallets with traditionally used barcodes, workers had to scan one by one. With RFID, those items can be read all at once by a portal reader placed at the dock door as they are unloaded from the truck. Unloading an inbound container, for instance, which may take about two and a half hours to individually scan, sort, and count cartons, may now take less than half an hour with RFID-tagged cartons.

Item-level Tagging at the Point of Manufacture

Tagging products at the source of manufacture is tasked with providing more accurate inbound and outbound information in those distribution centres as well as more efficient receiving and shipping processes at external sites.

Using passive or active RFID tags affixed to assets like products, containers, equipment and people, organizations can monitor in real-time location and status. Specialty tags have been developed to meet the needs of certain types of asset management, and this system has been successfully implemented many times in closed loop systems of returnable assets.

Traceability & RFID

RFID tags can be used to address government compliance mandates like “farm to fork”. The tags can store the necessary tracking information, from manufacture date, shelf life, expiration dates, lots, batch, serial numbers, etc. Using readers and portals throughout the supply chain, the data can be updated wirelessly and this electronic record can be made available in case of a recall or counterfeit issue.

Here are the top 5 reasons why RFID should be used in warehouses:

- Tags do not have to be seen in order to read data. This means that tracking products or people can happen from anywhere in a specified range which maximizes speed and efficiency.

- RFID tags can store up to 100 times the data of barcodes, allowing you to keep track of all the data you need for your inventory such as lot and serial number, size, manufacturer, vendor, expiration date, user, location on production line and anything else you might want to know.

- Readers can read up to 200 tags at once. This will increase speed and productivity since employees will not need to physically scan each label.

- The position of each tag is flexible (as long as they are not blocked by metal or water) since the tag doesn’t need to be physically seen by the reader. For example, you can place tags in boxes or within a pallet.

- RFID technology is functional inside and outside the warehouse. The technology has the capacity to withstand harsh environments and temperatures, even the tags!