Fixed Reader

Industrial Fixed RFID Readers for Continuous Automation & High-Volume Tracking

Morx Fixed RFID Readers provide reliable, long-range UHF identification for warehouse automation, manufacturing plants, and conveyor-based systems. Engineered for 24/7 industrial operation, they support EPCglobal Gen2 protocols and seamless integration with enterprise systems, making them ideal for mission-critical RFID automation.

Showing all 9 results

-

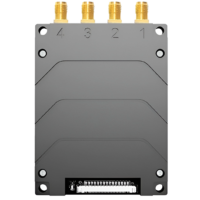

Impinj UHF Four Channel Module

Read more -

Impinj UHF Single Channel Module

Read more -

RFG Android 8 Port Fixed Reader

Read more -

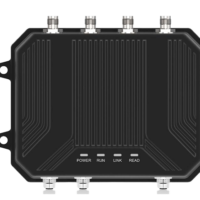

RFG CC04 Four Port Fixed Reader

Read more -

RFG H40 Four Port Fixed Reader

Read more -

RFG Linux 8 Port Fixed Reader

Read more -

UHF Forklift Reader/Writer

Read more -

Zebra FX9600

Read more -

Zebra FXR90

Read more

Industrial Fixed RFID Readers Built for Always-On Environments

Morx Fixed RFID Readers are purpose-built for environments where uninterrupted operation and accuracy are essential. Unlike portable devices, a fixed RFID reader is permanently installed to monitor assets, pallets, or vehicles in real time across production lines, gates, and storage zones.

With optimized RF output, stable read performance, and industrial-grade hardware, Morx solutions are widely deployed as fixed UHF RFID readers in factories, warehouses, and logistics facilities across India.

Technical Value: Why Morx Fixed RFID Readers Perform Better

Our fixed RFID reader portfolio is engineered for industrial automation systems that demand reliability, scalability, and consistent data capture.

Key technical strengths include:

- Support for EPCglobal Gen2 / ISO 18000-6C protocols

- High-speed anti-collision processing for dense tag environments

- Low-latency data handling for real-time workflows

- Stable RF performance for conveyor belt and gate-based systems

- Industrial-grade construction for continuous operation

These capabilities make Morx a trusted fixed RFID reader manufacturer for B2B deployments requiring long service life and operational accuracy.

Key Specifications Overview

- Read Range: Medium to long-range UHF detection (application dependent)

- RF Protocol: EPCglobal Gen2 / ISO 18000-6C

- Frequency Band: UHF RFID (region-specific configuration)

- Antenna Connectivity: External antenna ports for flexible read-zone design

- Housing: Rugged industrial enclosure

- Operation: Designed for continuous 24/7 usage

- Integration: API and middleware support for enterprise systems

For installations requiring precise read-zone control or extended coverage, fixed readers are commonly deployed with External RFID Antennas to optimize RF performance across gates, conveyors, and wide-area facilities.

Common Industrial Use Cases

Morx Fixed RFID Readers are widely used across industrial and logistics-driven environments:

- Fixed RFID reader for conveyor belt systems

- Fixed RFID reader for manufacturing plants

- Warehouse automation and pallet tracking

- Supply chain and logistics visibility

- RFID gate fixed reader for access and vehicle monitoring

In these applications, fixed readers ensure accurate, automated data capture without manual intervention, improving throughput and traceability.

Why Choose Morx RFID?

Morx RFID focuses exclusively on industrial-grade RFID solutions for B2B operations.

What sets us apart:

- Proven 24/7 operational reliability

- Experience as a fixed RFID reader supplier in India

- Technical pre-sales guidance and post-deployment support

- Readers designed for long lifecycle and scalability

- Strong expertise in RFID automation and system architecture

Our fixed readers are often integrated with industrial RFID Controllers to enable centralized device management and seamless system control in large-scale automation projects.

Frequently Asked Questions (FAQs)

Morx fixed RFID readers support standard APIs and RFID middleware, enabling smooth integration with ERP, WMS, MES, and custom enterprise software platforms.

Yes. Our readers are optimized for fast-moving environments and provide consistent tag reads on conveyor belts and automated production lines.

Depending on the model, Morx fixed readers support multiple antenna ports, allowing coverage of multiple read points using external antennas.

Technical Comparison: Fixed RFID Reader Types

| Product Type | Best For | Key Feature | Read Range | Environment Type |

|---|---|---|---|---|

| UHF Fixed RFID Reader | Warehouse automation, supply chain visibility, retail backrooms | High-speed anti-collision, EPCglobal Gen2 support | Up to 10–12 meters (with external antennas) | Warehouses, distribution centers, logistics hubs |

| Multi-Port Fixed RFID Reader | Conveyor belt systems, dock doors, RFID gates | Multiple antenna ports for wide-area coverage | Configurable per antenna zone | Manufacturing plants, automated sorting lines |

| Industrial Fixed RFID Controller Reader | Large-scale industrial automation and centralized control | Stable 24/7 operation, controller integration, low latency | Medium to long range (application-dependent) | Factories, outdoor yards, harsh industrial environments |